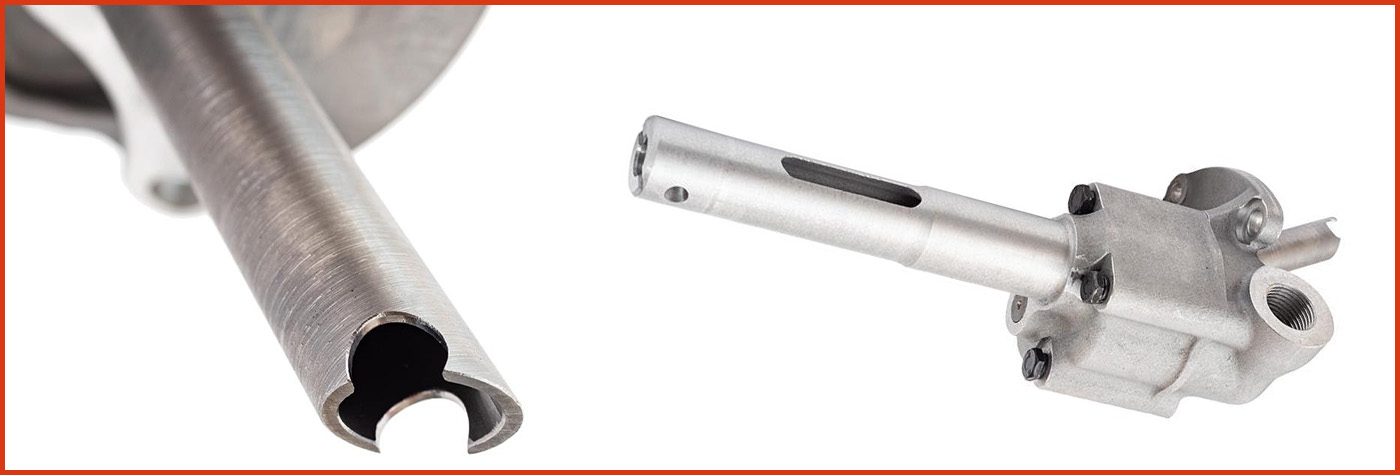

Oil pressure is the lifeblood of your Healey’s four-cylinder engine. Early cars often suffer from uneven oil flow as tolerances widen with age. This new oil pump has been digitally modelled in CAD to original factory dimensions, CNC-machined from British castings, and hand-assembled in the UK. The result is consistent lubrication whether you’re touring long-distance or heading out for a spirited drive.

Beyond protecting bearings, a properly engineered oil pump minimises cold-start delays and stabilises hot-idle pressure. In other words: less wear, fewer surprises, and more confidence every time you fire up your Healey 100.