Posted: Tuesday, 25 March 2025 @ 13:27

A New Dawn is Rising in the Austin-Healey World

We are excited to announce the arrival of our new Austin Healey 100 Iron and Alloy cylinder heads after 3 years in development and considerable investment.

Never before have Austin Healey iron cylinder heads been reproduced until now, and our high quality alloy heads are unrivaled by anyone else.

Ground Breaking New Cylinder Heads

The tooling pattern was CAD designed and CNC machined for accuracy to ensure high quality castings. Our new improved port design was achieved after weeks of extensive flow and dyno testing.

Below are just some of the key points why our Cylinder heads are of the highest quality available anywhere.

Key features include:

- All tool pattern work has been CAD designed and CNC machined for accuracy to ensure the highest quality castings.

- Our new ultimate port design developed during extensive flow and dyno testing.

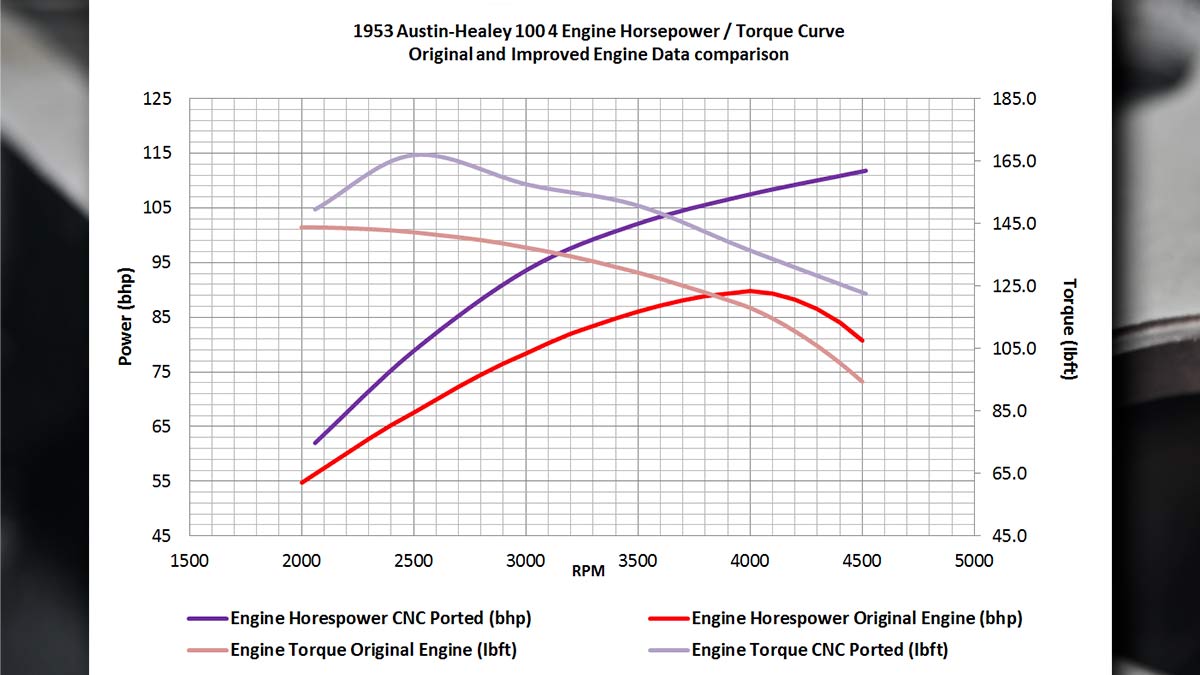

- Significant BHP and Torque power gains when tested on our development engine using H4 carburettors and all standard engine components including the O.E. cast iron exhaust manifold and a slightly higher compression ratio. See the results for yourself on our dyno reading!

- Designed in CAD with increased wall thickness where required to allow additional porting work if required.

- Using only cutting edge CNC machining centres with state of the art CNC porting.

- Over 14 hours of meticulous machining with 4.5 of those on CNC porting alone.

- All heads are fully CNC Ported so flow is identical over all of the ports. (Not left with the bare cast surface which is uneven between cylinders and will not guarantee even flow.)

- State of the art pressure tested CNC cut seats to provide a perfect valve seal every time.

- Each individual valve inspected and measured.

- Pressure tested 3 times during the machining process.

- Each casting is vacuum impregnated so total assurance against even the smallest of blind porosity which could break open during the life of the head.

- Each valve seat is meticulously machined and installed and so will not distort or regress up inside the head casting over time.

- Colisbro-Bronze guides with 3000 competition valves and modern stem seal.

- Only the finest materials used. Heat treaded LM25 for the alloy castings.

- Assembled Alloy Heads weigh only 11.5kgs, saving a massive 13.8kgs over the O.E. iron heads.

- Assembled and tested by Master Engine builders.

- Redesigned combustion chambers and ports allowing slightly higher compression ratio for increased performance and efficiency.

If you follow us on our social media, you may recall a couple of our recent posts teasing our new alloy cylinder heads, which we installed on one of our Healeys in our showroom.

Cast Iron Austin-Healey Cylinder Head

ENG591

Austin-Healey Cast Iron Fast Road Cylinder Head - Gasflowed

Application: BN1 - BN2

Aluminium Austin-Healey Cylinder Head

ENG592

Austin-Healey Aluminium Fast Road Cylinder Head - Gasflowed

Application: BN1 - BN2